The scope of the project was to replace the existing cast iron boilers and water heater with three high efficiency modular gas fired boilers. Boiler #3 is equipped with an internal copper coil to produce domestic hot water as well as heat, eliminating the need for a separate gas-fired water heater and the 1000 gallon hot water storage tank.

Removal of Old Equipment

New Equipment Installation

Boilers: Two Triad Model G-PS-1600-SH-HEP, One Triad Model G-PS-1600-SH-C-DHW-HEP

Burners: Powerflame Model CR2-G-MOD Firing Natural Gas

Burners: Powerflame Model CR2-G-MOD Firing Natural Gas

Main Circulating Pumps: Two Flo-Fab Model 1000-C1050A, Capacity 900 GPM at 80' Head

Circulator Pump VFDs: 30 HP Dura Pulse equipped with line reactors

Sensor Wetting Pump: Flofab Series 600

Circulator Pump VFDs: 30 HP Dura Pulse equipped with line reactors

Sensor Wetting Pump: Flofab Series 600

Controls

|

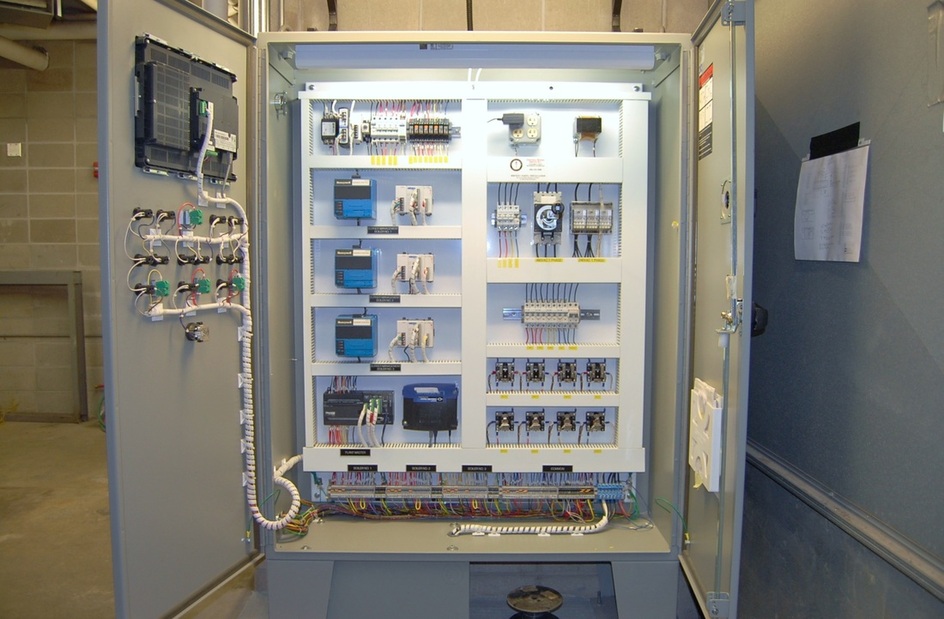

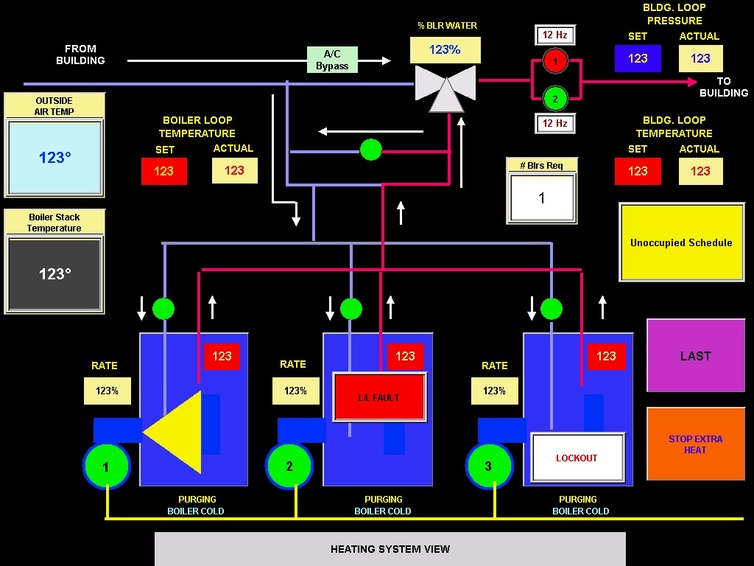

The PLC-based control system is housed in a free standing control cabinet featuring a 15" color touch screen from which all operations and set points are viewable and adjustable. This system is Ethernet based to permit remote access from a PC or an iPhone. The control cabinet includes individual burner management controls. |

|

The plant master controller provides lead-lag control and staging of the boilers based on the load required. In addition, it provides setback operation of the boiler plant controlled by the internal clock and calendar. The plant master also controls the operation of the building's circulator pumps using lead-lag control and variable speed controls. |

Interested in energy savings and increased efficiency? Click here to contact us.